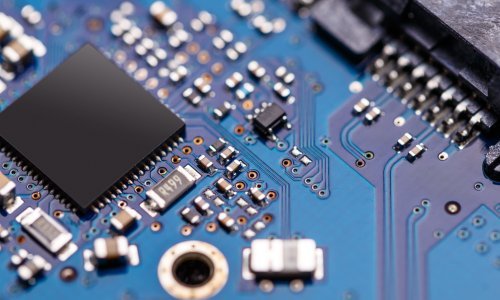

The U.S. is witnessing a major revival in semiconductor manufacturing, thanks to the CHIPS Act incentives. Passed in 2022, the CHIPS and Science Act is now making waves across the tech and manufacturing sectors. Billions of dollars in federal funding are being invested in bringing semiconductor production back to American soil.

This move is not just about creating jobs—it’s about securing the country’s technological future, reducing dependence on foreign supply chains, and keeping up with global competition. From Intel to TSMC, major semiconductor companies are expanding or building new chip factories across the U.S., driven by the promise of government support and long-term economic security.

What is the CHIPS Act?

The CHIPS (Creating Helpful Incentives to Produce Semiconductors) and Science Act was signed into law by President Joe Biden in August 2022. The law provides over $52 billion in incentives, grants, and funding aimed at reviving America’s chip-making industry.

Key goals of the CHIPS Act include:

- Strengthening the U.S. semiconductor supply chain.

- Encouraging domestic research and innovation.

- Reducing reliance on East Asia for chip production.

- Creating high-paying jobs in manufacturing and engineering.

- Supporting national security and advanced defense technology.

Why the CHIPS Act Was Necessary

The global chip shortage that started during the COVID-19 pandemic exposed the risks of overdependence on foreign chip manufacturers, especially in Taiwan, South Korea, and China. Shortages disrupted the production of everything from smartphones and laptops to cars and medical devices.

Meanwhile, the U.S. share of global semiconductor manufacturing had dropped from 37% in the 1990s to just 12% in recent years. This decline raised alarm bells in Washington and led to bipartisan support for the CHIPS Act.

CHIPS Act incentives are designed to reverse this trend and restore America’s leadership in advanced chip production.

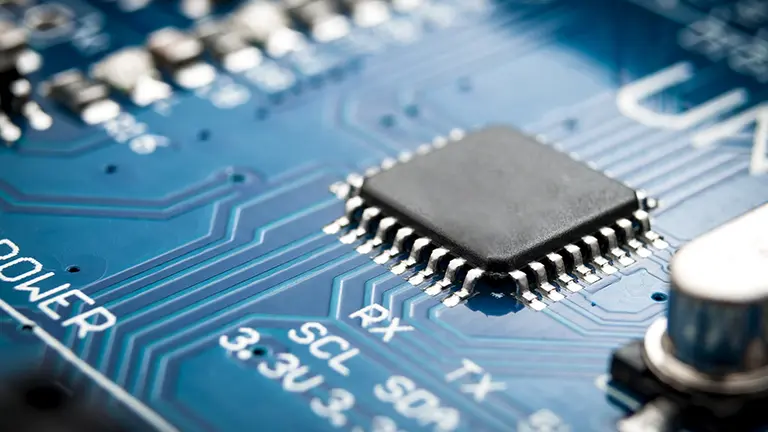

Major Semiconductor Companies Expanding in the U.S.

Thanks to the CHIPS Act incentives, many top semiconductor companies have announced major investments in U.S. chip production. Let’s look at some of the key players and their plans.

Intel: A $100 Billion Bet on American Chips

Intel, a longtime leader in the chip industry, is investing over $100 billion in new semiconductor factories (also called fabs) in Ohio. The site, dubbed the “Silicon Heartland,” is one of the largest private-sector investments in Ohio’s history.

Key highlights:

- Two advanced chip fabs to begin operations by 2025.

- Over 7,000 construction jobs and 3,000 long-term jobs expected.

- Focus on producing advanced logic chips for AI, cloud computing, and defense.

Intel CEO Pat Gelsinger stated, “The CHIPS Act incentives give us the confidence to invest in long-term domestic manufacturing. We want to build the future of computing right here in America.”

TSMC: Bringing Taiwanese Precision to Arizona

Taiwan Semiconductor Manufacturing Company (TSMC), the world’s largest chipmaker, is building two advanced fabs in Phoenix, Arizona.

Project scope:

- First fab producing 5nm chips, with operations starting in 2025.

- Second fab to produce 3nm chips—the most advanced in the world.

- Total investment: $40 billion.

TSMC’s expansion is crucial for U.S. tech giants like Apple and Nvidia, which rely heavily on the company’s cutting-edge chips.

Samsung: Investing Big in Texas

Samsung, the South Korean tech giant, is building a $17 billion chip plant in Taylor, Texas. This is part of a broader plan to increase U.S.-based chip production.

Plant features:

- Expected to begin operations in 2026.

- Will focus on advanced 3nm and 5nm chips.

- Thousands of high-skilled jobs for engineers and technicians.

Samsung has also hinted at further expansion depending on CHIPS Act funding outcomes.

Micron: Leading in Memory Chip Manufacturing

Micron Technology, a U.S.-based memory chipmaker, is building a massive new fab in Clay, New York. The company announced a $100 billion investment over 20 years.

Plans include:

- Creating up to 50,000 jobs in the region.

- Boosting domestic production of DRAM chips.

- Starting construction in 2025.

Micron’s project is being touted as the “largest single private investment in New York state history.”

How CHIPS Act Incentives Work

The CHIPS Act offers financial incentives in the form of:

- Direct grants: Cash provided to companies for new construction and expansion.

- Tax credits: Up to 25% for investments in chip manufacturing equipment and facilities.

- Research & development funding: Grants for universities, startups, and national labs working on chip innovation.

- Workforce training programs: Funding for community colleges and technical schools to build a pipeline of skilled workers.

To receive CHIPS Act funding, companies must:

- Commit to building and operating facilities in the U.S.

- Avoid using funds for stock buybacks or executive bonuses.

- Support workforce development and supply chain partnerships.

Economic and Strategic Impact of CHIPS Act Incentives

The impact of CHIPS Act incentives goes far beyond job creation. It touches nearly every corner of the economy and national strategy:

1. Job Growth and Economic Development

The semiconductor projects have already started bringing thousands of jobs to states like Arizona, Ohio, Texas, and New York. These jobs range from construction and engineering to high-tech research and manufacturing.

States and local governments are offering additional tax breaks, land grants, and training support to attract more investment.

2. National Security

Semiconductors are critical for defense technologies like radar systems, missiles, and encrypted communications. Having domestic production ensures that the military has a secure and reliable chip supply.

3. Supply Chain Resilience

The CHIPS Act aims to reduce the U.S.’s dependence on chips from China and Taiwan. This not only minimizes supply chain disruptions but also protects against geopolitical risks.

4. Innovation Boost

With billions in funding going to R&D, universities and startups now have more support for developing next-generation chip technologies, including:

- Quantum computing chips

- AI-optimized processors

- Energy-efficient semiconductors

Challenges and Roadblocks

While the CHIPS Act incentives are helping drive investment, the road ahead isn’t without obstacles:

1. Workforce Shortages

There’s a shortage of skilled workers like chip engineers, fab technicians, and automation specialists. The U.S. education system is racing to fill the gap, but it will take time.

2. Global Competition

China, Europe, and South Korea are also heavily investing in their semiconductor industries. The U.S. must continue to innovate to stay ahead.

3. Long Timelines

Building a semiconductor fab takes years. Most of the announced plants won’t be fully operational until 2025 or later.

4. Rising Costs

Construction costs for chip fabs are rising, and delays due to supply shortages or permitting issues can be expensive.

What This Means for the Average American

Most people don’t think about semiconductors until they can’t buy a car, phone, or game console due to chip shortages. But these tiny devices are at the heart of modern life—and the U.S. is now working to take control of their future.

Thanks to the CHIPS Act incentives:

- New job opportunities are being created in both urban and rural areas.

- The cost and availability of electronics may stabilize.

- Innovation in sectors like AI, defense, and clean energy will grow faster.

Conclusion: A Turning Point for U.S. Technology

The CHIPS Act incentives represent more than just government spending—they symbolize a bold step toward reclaiming America’s role as a global tech leader. With billions in investments, thousands of new jobs, and a renewed focus on research and innovation, the U.S. semiconductor industry is set for a powerful comeback.

Though challenges remain, the momentum is strong. As Intel, TSMC, Samsung, and Micron expand their American footprints, the future of chipmaking is looking increasingly red, white, and blue.

Read Next – Renewable Energy Manufacturing Booms in Texas and Arizona